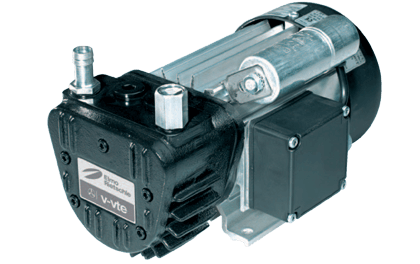

- Dry running and oil lubricated rotary vane pumps from Elmo Rietschle covering a wide performance range

- The V-Series is known for its low noise level, ease of operation, and low oil consumption on oil lubricated machines

- Flexible maintenance and service agreements are available

Rotary Vane Vacuum Pumps

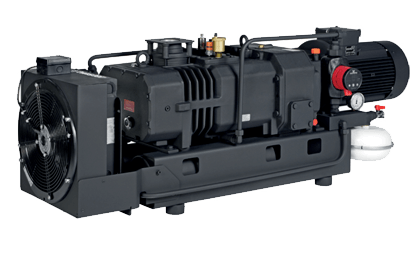

Mid-tech is a main distributor for Elmo Rietschle dry running and oil lubricated rotary vane pumps which cover a wide performance range. The eco-friendly dry running rotary vane pumps are used for vacuum, pressure and combined pressure and vacuum applications. Dry running pumps are so called because they do not use operating fluid. The rotor vanes are self-lubricating. The time-tested oil lubricated rotary vane machines are typically used for generating vacuum.

A rotary vane vacuum pump is a positive-displacement pump. There are vanes mounted to a rotor which then rotates inside a chamber. It is this rotation that compresses air, pushing it through the pump chamber toward the exit. Mattei describes a rotary vane compressor as “a volumetric rotary compressor, consisting of a rotor (with longitudinal slots in which the vanes slide) rotating within a stator (or cylinder).The rotor is offset in the stator so that when it turns on its axis, the vanes are pushed against the stator by centrifugal force.”

The pump is the core of the rotary vane air compressor, which is a very popular type of compressor, useful to many varied industries, with its energy saving ability and low cost efficiency. They are considered durable due to their construction, which is basically a single off-set rotor with the vanes sliding in and out. Fewer parts mean that there are fewer components to maintain. The V-Series is known for its low noise level, ease of operation, and low oil consumption on oil lubricated machines.

Oil lubricated rotary vane pumps often use a gas ballast valve. The ballast is a passage into the compression cavity that has an air flow, controlled by a cap on the pump’s exterior. A gas ballast lets air into the compression cavity so the pressure can reach atmospheric pressure, preventing evacuated vapours from condensing. The exhaust is returned to the atmosphere. This exhaust can contain water and solvent vapour as well as other contaminants. The gas ballast does cut back on contamination.

One of the primary causes of pump problems is contamination of the pump oil. Oil should be changed on a regular basis and filters monitored to prevent liquids and solids from from damaging the pump. A rotary vane pump is a robust piece of equipment, with long up times.

Even with fewer moving parts and its reliability, all the V-Series benefits from regular maintenance. Its functioning lifetime is easily extended with routine maintenance and repairs as needed. Mid-Tech provides flexible service agreements to suit your needs and systems regardless of their working environment. We also accommodate one-off servicing and repair for your convenience.

With all of the parts, tools and expertise you need, and same day call-out response available should your system need immediate attention, Mid-Tech offer a dedicated and professional service. For more information on our how we might be of service with your rotary vane vacuum pump requirements, please call 0800 028 8366 or click to contact us here.