- Diverse range of technology solutions for professional and industrial applications.

- Liquid ring, vane, lobe, radial, claw, and screw pumps available.

- Easy installation, service & maintenance provided by Mid-Tech engineers.

Screw pumps, rotary vane pumps and other vacuum solutions from MidTech

Need a reliable replacement vacuum pump? Or, looking for an efficient vacuum for your new installation? Mid-Tech are here to support you. Mid-Tech are air specialists, offering a variety of state-of-the-art products and services to our customer base across the Midlands. We are a dedicated supplier, intent on forming long term relationships with our clients and delivering personalised customer service. That’s why Mid-Tech partners with some of the industry’s leading vacuum and pressure brands. We are proud distributors of brands that provide world leading technology, innovative solutions, and premium performance.

Elmo Rietschle is the first choice for industrial vacuum and low pressure solutions. Whatever your process and requirements, Elmo Rietschle has an advanced and efficient solution for you. Their products are designed to offer amazing plug ‘n’ play efficiency, providing quick and easy installation with maximum reliability and results. In fact, every Elmo Rietschle product is designed with the intention of improving your process, making it safer, increasing your efficiency, and minimising your downtime. That’s why Elmo Rietschle continues to invest in product development, ensuring their offering is at the forefront of modern technology for the industries and customers they serve.

Their product range offers a variety of technologies including rotary screw pumps, liquid ring, rotary vane, lobe, radial, claw, and side channel blowers. Delivering an amazing portfolio of both oil lubricated and dry running machines, this outstanding range offers a vast choice to customers, allowing them to find the optimal solution for their needs.

The Elmo Rietschle range

Radial

The F Series are robust and economical single and multi stage radial blowers for vacuum and pressure operations. They come in a wide variety of sizes and can be used for both suction and pressure in industrial processes. These fans are especially suited to the packaging and paper industries where they can be used for extracting dust and fine material.

Variable frequency drives are available for optimised efficiency.

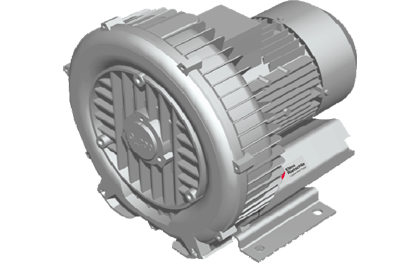

Side Channel

G Series side channel blowers are a reliable and proven technology. They have provided flawless performance day after day for decades and have been a tried and tested solution for many industries. The G Series is available in a wide performance range up to 3,000 m³/h and differential pressures of up to 1,000 mbar. They offer flexible and powerful performance and come in a virtually maintenance free and lightweight design.

Liquid Ring

The L Series of liquid ring vacuum pumps has been specially designed for extreme conditions. Wet and humid processes can lead to limescale, abrasion, and other issues that, over time, will downgrade the performance of the pump. The L Series has been engineered with these specific challenges in mind. Stainless steel shafts ensure they are corrosion resistant, offering safe ongoing performance, whilst ceramic coating ensures the pumps do not calcify due to fluid deposits.

Lobe

Primarily used in applications that need coarse or fine vacuum for handling gases and vapours, rotary lobe vacuums offer robust performance. The R-VWP is dry running with no grease or oil in the compression chamber.

Claw

The C Series dry claw pumps generate contact free vacuum efficiently and economically. They rely on innovative technology that focuses on the principle of internal compression in the claw design. This provides significant energy savings for customers whilst offering higher efficiency compared with traditional blower designs that do not offer internal compression.

Explosion proof and ATEX compliant models are also available.

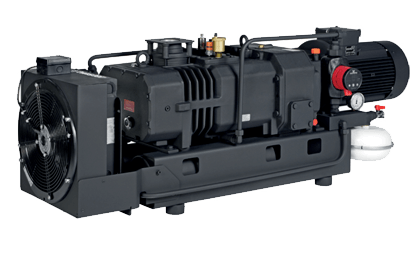

Screw

The S-VSI is a state-of-the-art oil free screw pump that is efficient, reliable, and also offers extremely low life cycle costs. As it’s dry running, it guarantees no process contamination and no pollution caused by pump operation. In the pump housing, two rotors (both timing gear synchronised) turn in opposite directions. The gearbox is lubricated and cooling is achieved through the continuous flow of coolant through the pump housing. Elmo Rietschle pumps feature high vapour and liquid tolerances and low rotational speed ensures low noise and low vibration levels during operation.

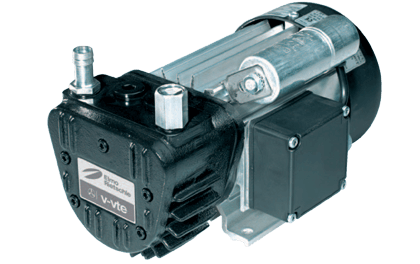

Vane

Rotary vane technologies are available in both dry running and oil lubricated models. Available in a wide performance range, oil free rotary vane pumps feature maximised cooling air pathways, heat resistant materials, and sound reduction covers. Lubricated models have been time-tested and are typically used for generating vacuum.

Why choose Elmo Rietschle?

- Long history of product and application know-how

- Precise knowledge of industrial processes

- High-quality products

- Unmatched range of vacuum and pressure technologies

Industries and Applications

Many industries see Elmo Rietschle as the first choice for vacuum and pressure, providing solutions that offer unrivalled reliability and performance in the following areas:

- Chemical

- Pharmaceutical

- Printing & paper

- Packaging

- Food packaging

- Environmental

- Industrial parts cleaning

A large choice of technologies means that Elmo Rietschle can cater to your specific application requirements, whatever your industry. For help choosing a solution that’s right for you and your business, speak to an expert engineer at Mid-Tech. Mid-Tech engineers are professional air experts and are factory trained on all the technology we distribute. We are also available for installation, servicing, repairs and maintenance. To get in touch with us, please call 0800 028 8366 or click here to fill out our contact form.