- Mid-Tech sell, install, service and repair a wide variety of vacuum pump & blower technologies

- Centrifugal, side channel, compact liquid ring, rotary vane and lobe, claw & screw

- We provide genuine aftermarket parts and supplies on all pump and blower products

Rotary Vacuum Pumps and Blowers, plus other Innovative Technologies

Rotary vane vacuum pumps drive rotary vane air compressors. The durable construction is a single off-set rotor with the vanes sliding in and out. Rotary vacuum pumps are not the same as rotary vane vacuum pumps. They are used for many industrial applications in a variety of industries. Their use is not limited to rotary vane pumps. Another type of rotor driven vacuum pump is the liquid ring vacuum pump.

The NASH by Gardner Denver liquid ring vacuum pump was the first of its kind when it appeared in 1905. Its enduring popularity is due to its durability, among other features.

A liquid ring pump has a round pump body with an eccentric rotor: The rotor spins the liquid inside the pump which forms a rotating liquid ring on the inner surface of the body. Hence the name, liquid ring.

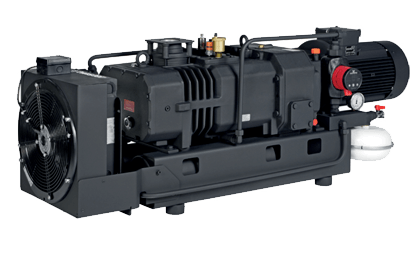

The rotary lobe pump is another type of rotary vacuum pump. It’s a dry running positive displacement pump. There is no oil or grease in the compression chamber where two non-contacting triple lobed rotary lobe rotors rotate against each other. The gear box and bearings are oil lubricated. They are separated from the pumping chamber.

Elmo Rietschle C-Series dry claw vacuum pumps are yet another rotary vacuum pump. These pumps use internal compression in the rotary claw design. The claws roll together without contact, and are synchronised by a precision gear set. Seals separate the compression chamber and gearbox. The claw rotors transport air by opening and closing the inlet and outlet channels.

A gas ballast is how air gets into a vacuum pump and it allows the pump to displace vapour that would otherwise condense in the pump if there were no gas ballast. The gas ballast allows the vapour to be displaced by opening the outlet valve before the vapour condensates. Both the vapour and the ballast gas are discharged. Atmospheric air or selected inert or process gases are used as ballast gas. Gas ballasts increase the attainable base pressure of a vacuum pump.

Mid-Tech also supplies a wide range of vacuum pump parts. These parts include gasket sets, O rings and clean and overhaul kits for high pressure vacuum pumps, pump blades for all makes of vacuum pump, high pressure vacuum rotors and starters, springs and seals for vacuum repair, rotary vane pump spares, vacuum pump bearings and shaft sleeves, wilson and conical seals, electric motors and exhaust valves.

Our service team is experienced in all the products used in the compressed air industry. We provide maintenance and genuine aftermarket parts and supplies on all products we supply. Mid-Tech also provides flexible service agreements to suit your needs and systems regardless of their working environment. We also offer one off service deals at your convenience. We have the parts, tools and expertise you need. Same day call-out response is available should your equipment break down. For more information on our rotary vacuum pumps, please call 0800 028 8366 or contact us below.